Out Of This World Tips About How To Achieve Continuous Improvement

Identify the importance of tools in deploying continuous improvement.

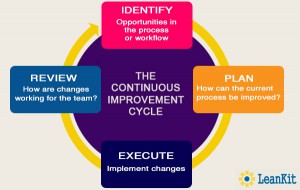

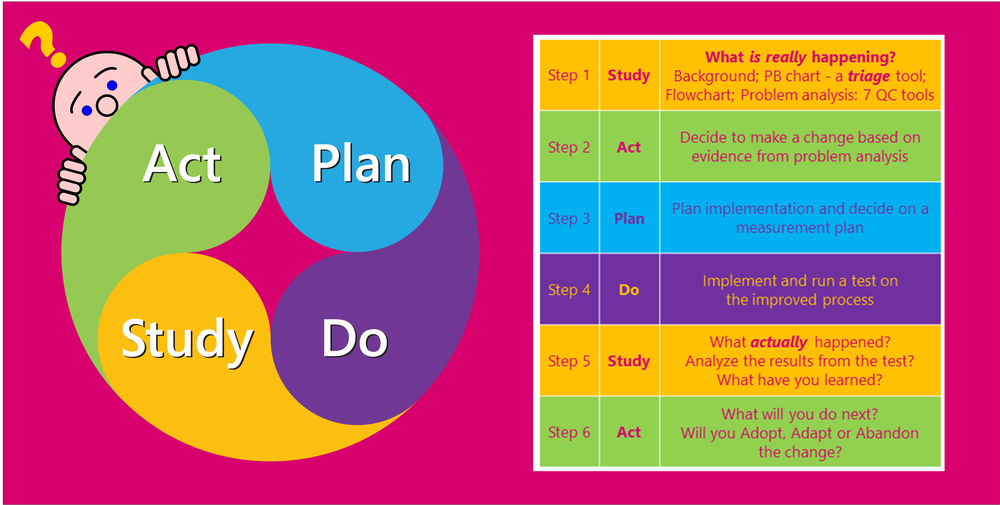

How to achieve continuous improvement. It is especially important that the right tools and methods are used. Collection of ideas in the continual improvement. Think about where you want to take your organization in the future.

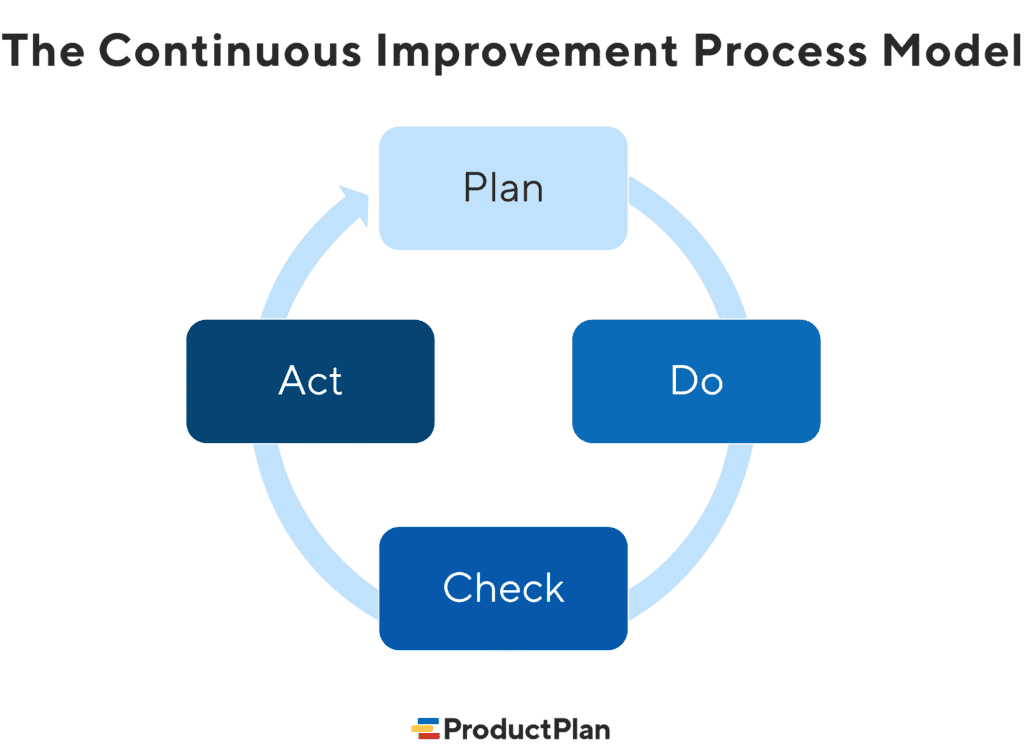

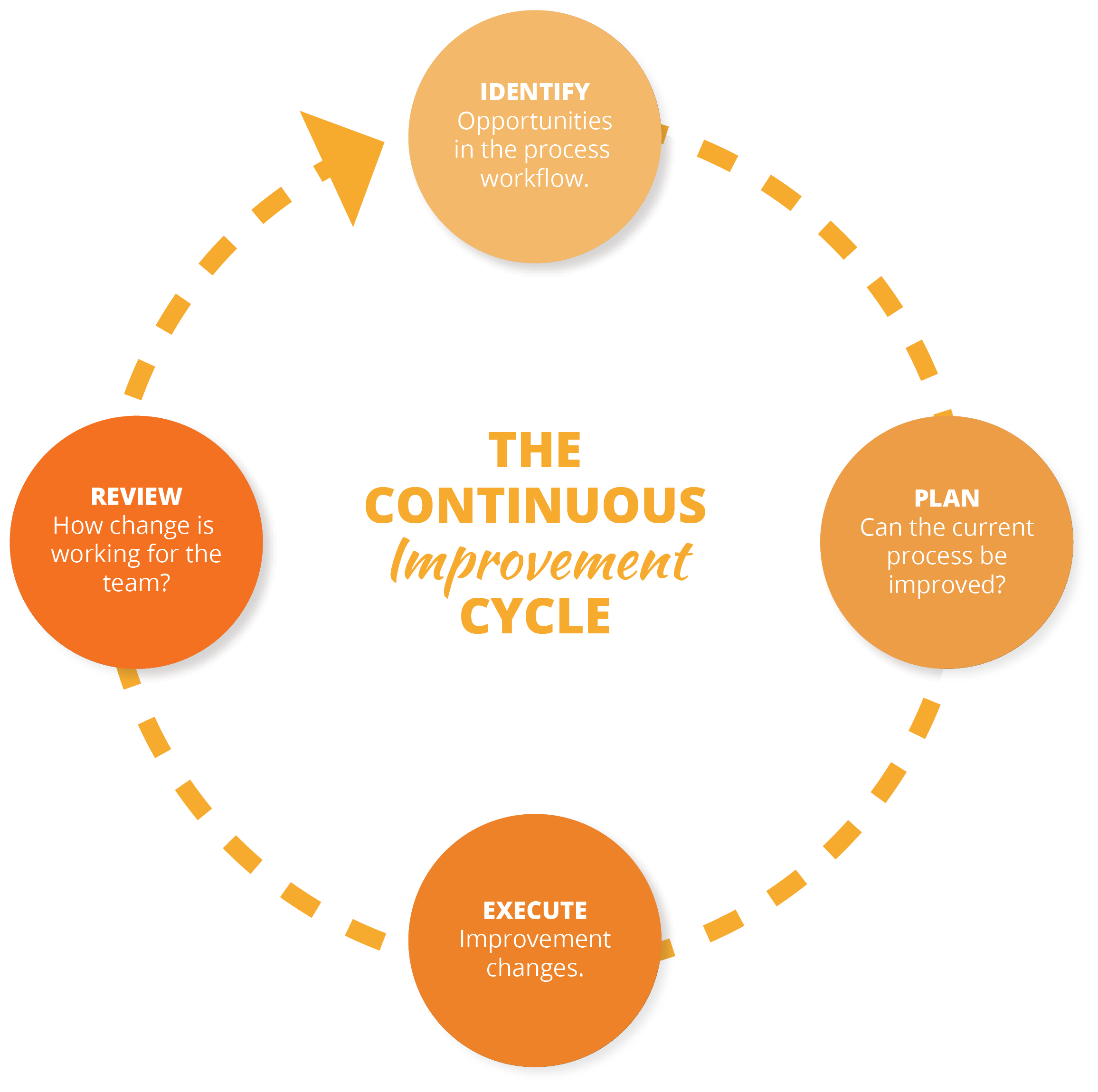

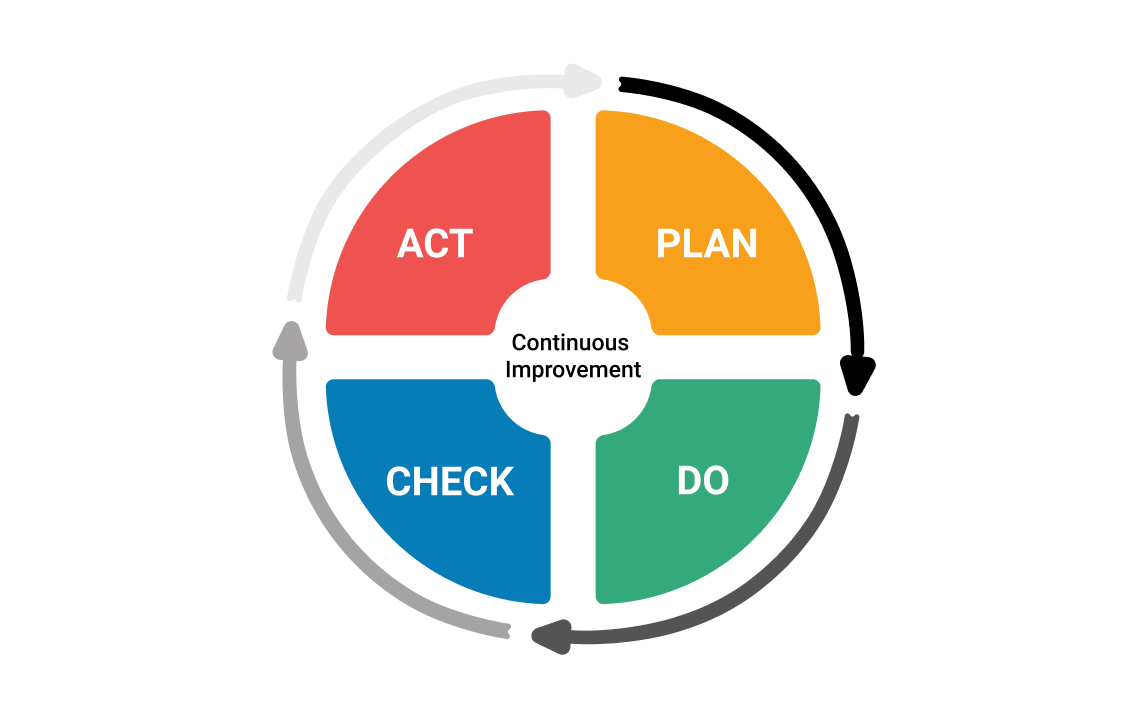

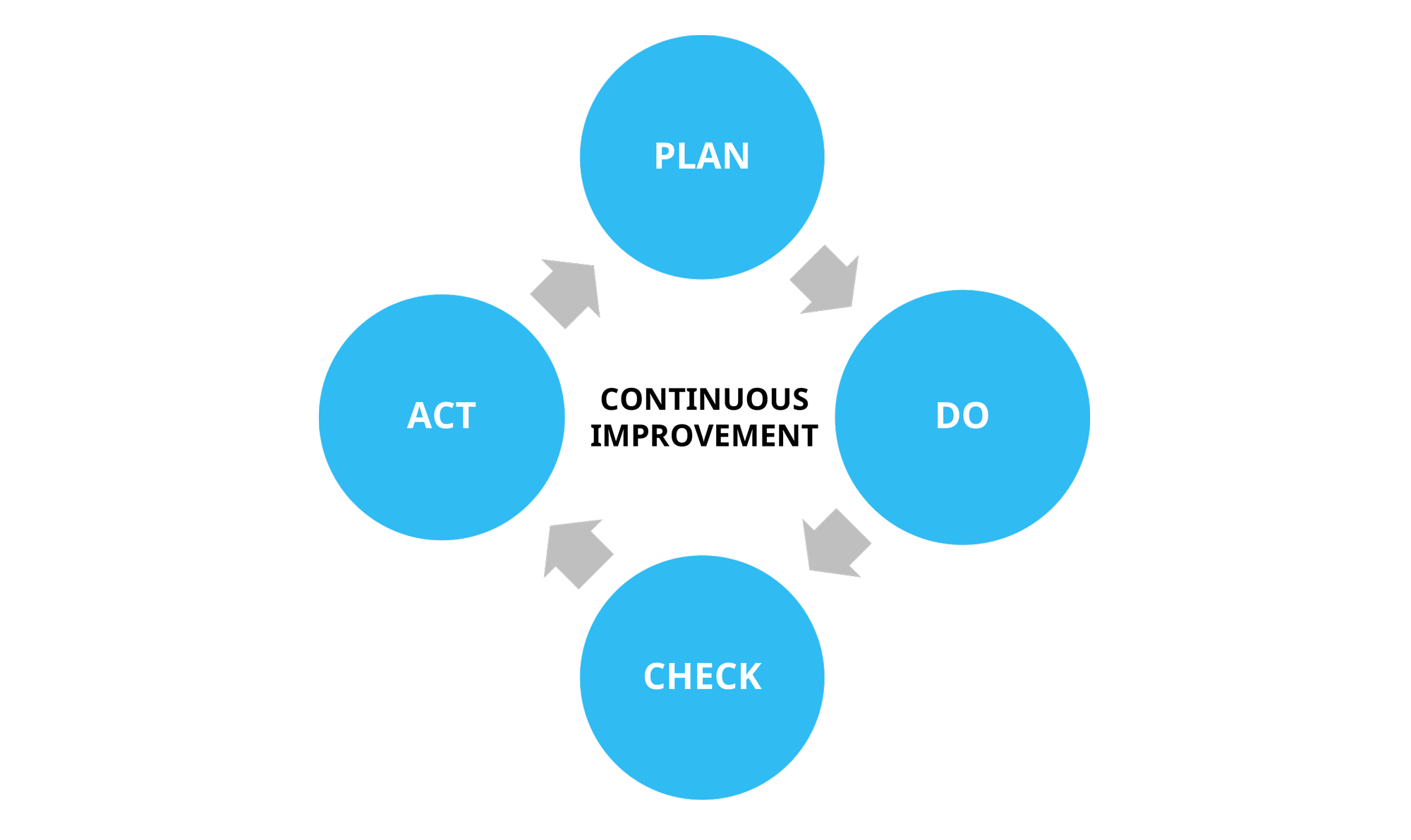

Five simple steps to achieve continuous improvement: Continuous improvement in manufacturing involves taking an established production process and looking for multiple ways to incrementally improve the production process. Before developing your own continuous improvement model, it can help to.

Determining an ideal end goal can. All alison courses are free to enrol, study and complete. To achieve this, one needs to establish unity across the organization with common goals and clear leadership.

An example would be reducing picking cost for a certain customer from $2.50 per pick to $2.25. Implement the kaizen method the term comes from “kai”, a japanese word meaning change, and “zen”, which refers. Make business improvement workshops a weekly habit.

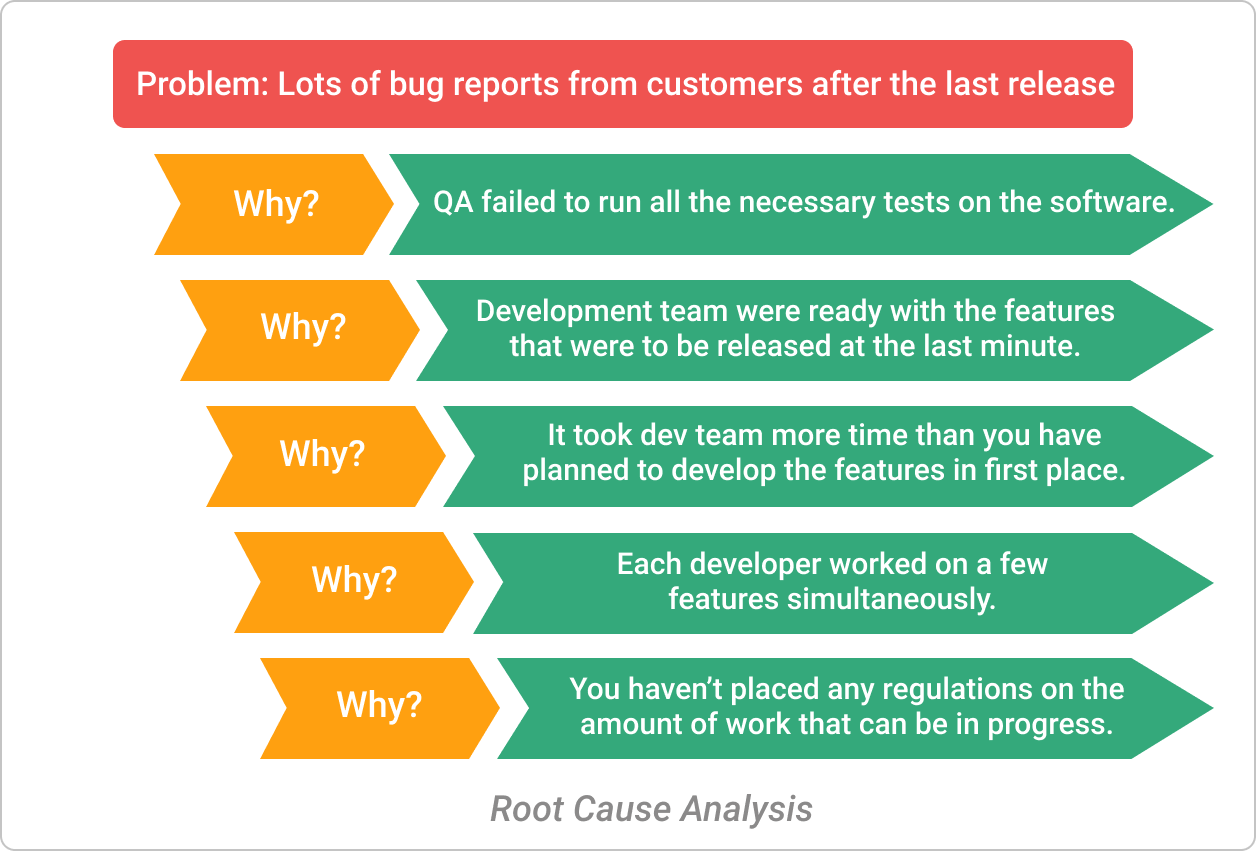

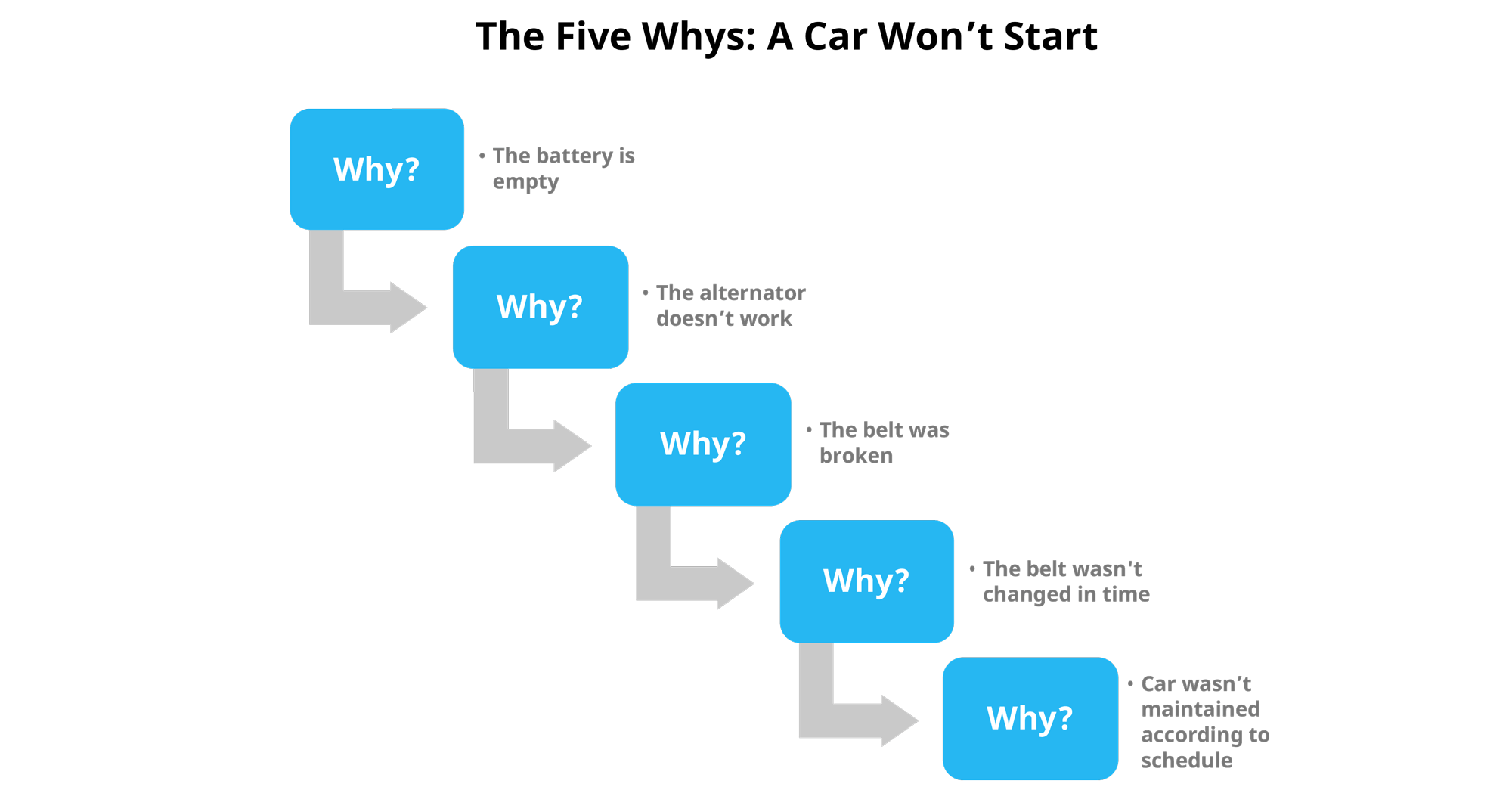

Define the current state or condition: To achieve continuous improvement, enterprises need to perform regular testing and deployment to ensure that the solutions meet business needs. Describe the current situation as thoroughly as you can.

Whether or not you choose to use one of these approaches, you can still achieve rapid continuous improvement for your business if you keep these core concepts in mind. 5 ways to integrate continuous improvement into your organization 1. Research popular continuous improvement models.